产品介绍

一、产品简介:

超高吸附量除磷树脂是一种具有特种功能基团的聚合物树脂,对磷酸根具有专一选择性,该树脂具有吸附容量大、选择性高、耐酸碱性能优异等特点,较同类产品,该树脂用量更少、树脂使用寿命更长,操作更简便,出水稳定维持在1ppm以下。超高吸附量除磷酸根树脂耐酸碱水平高,在含有氯离子、硫酸根、硝酸根、磷酸根的体系中对磷酸根选择性良好,磷酸根吸附性能优异。

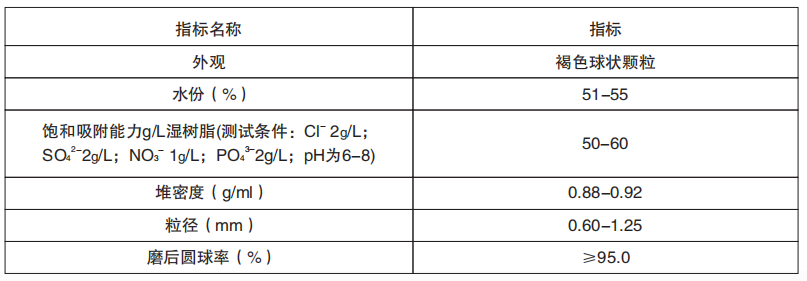

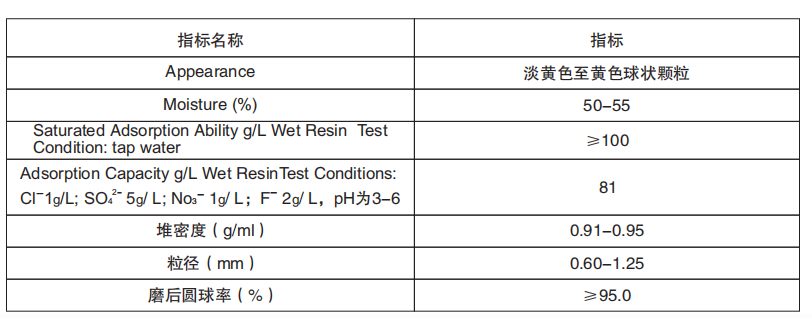

二、性能指标:

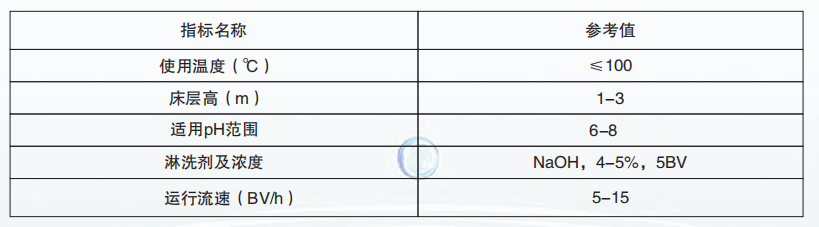

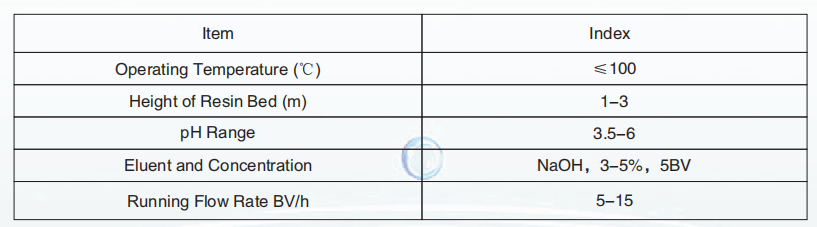

三、使用时参考指标:

四、树脂使用须知:

1.清洗离子交换塔及管道,保证容器和管道无杂物;

2.除磷酸根树脂的装填至离子交换塔,至规定高度后,摊平树脂,封堵人孔,试压检漏;

3.调整阀门至逆流清洗状态,用去离子水清洗树脂至出水清澈透亮;

4.切换阀门至正吸附状态,调整流量值5-15BV/h,即可进入使用;

5.检测出水水质,当磷酸根在线检测数值超过规定限制后及时切换下一塔吸附,本塔进入解析状态;

6.解吸塔先用去离子水冲洗3BV,然后用去离子水配制的4-5%的氢氧化钠溶液进行解吸5BV,然后用去离子水清洗至pH9-10,进入待吸附状态。

The Ultrahigh Adsorptione Dephosphorization Resin

1.Product Introduction

The ultrahich adsorption dephosphorization resin is a polymer resin with special functional groups, which has specific selectivityor phosphate radical. The features include high adsorption capacity, better selectivity, hich processing precision. Compared withsimilar products, the resin consumption is less and the service life is onger under the same condition. This resin is simple to operateThe effluent can be maintained stably below 1 ppm.

The ultrahich adsorption dephosphorization resin has high acid and alkali resistant. lt has beter selectivity for phosphate in thesvstem containina chloride ons. sulfate. nitrate and phosphate radical, so it has excellent dephosphorization performance.

2. Performance index

3 Reference index for Operation

4.Instructions forOperation

1.Clean the ion exchange tower and pipe to ensure that there is no other things in the container;

2. After loading the dephosphorization resin into the specified height of the ion exchange tower, ensure the resin is flattened, the hole is blocked, and the pressure is tested for leakage;

3. Adjust the valve to countercurrent cleaning state, clean the resin with deionized water until the water is clear.

4. The operation can be started after switching the valve to the positive adsorption state and adiusting the flow value to 5-15BV/h

5. The effluent quality needs to be tested. When the on-line detection of phosphate radical exceeds the specified limit, the columnenters the desorption state and switch the next column adsorption in time.with deionized water first, and then desorption to 5BV with 4-5% NaOH solution prepared

6.Desorption tower needs to wash to 3Blwith deionized water. and finalv c ean with deionized water to p- 9-10. then enter the state to be adsorbed